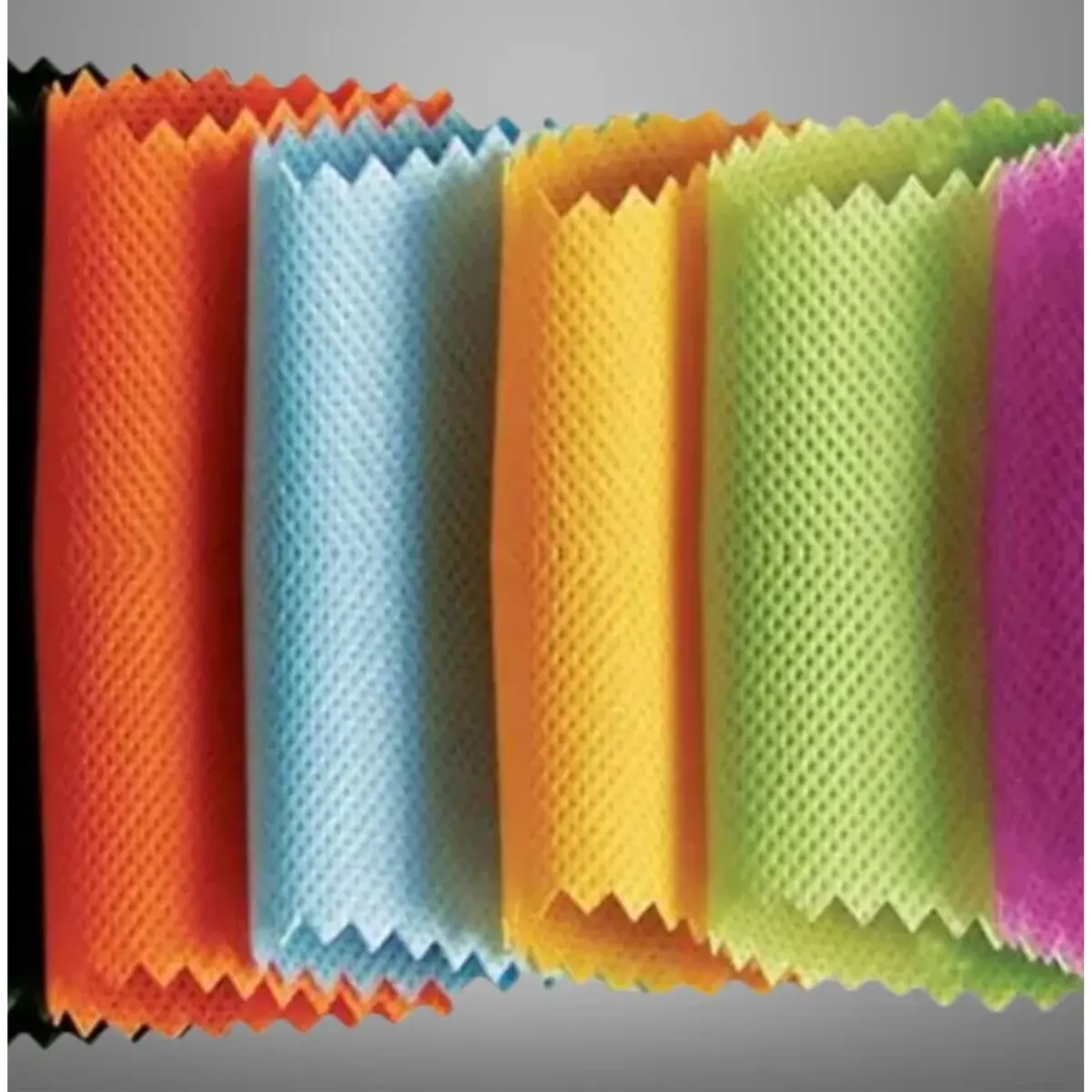

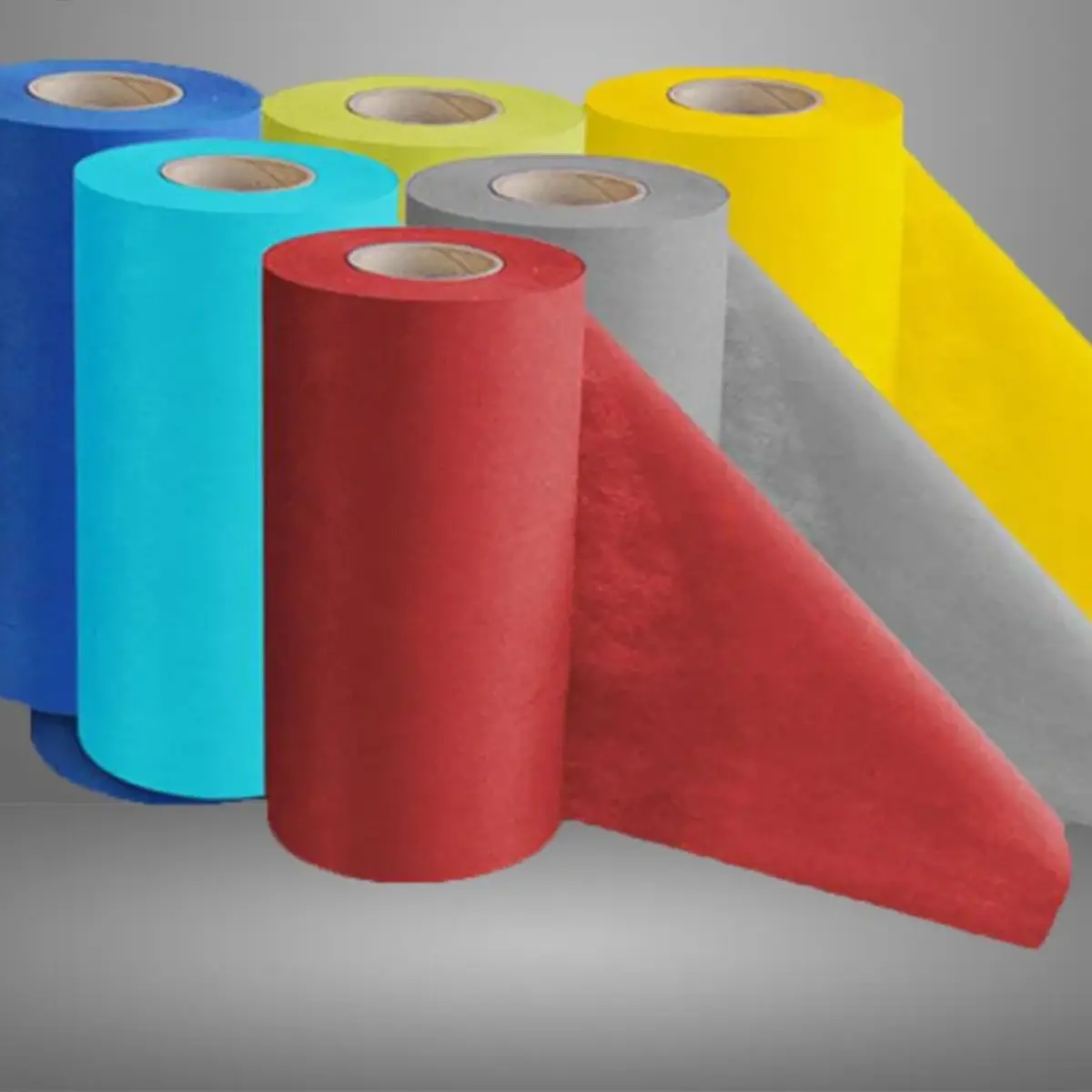

PP Spunbond Nonwoven Fabric

Polypropylene spun-bond non woven fabric is a type of non woven material made from polypropylene (PP) fibres. It is produced using a process called spun-bond technology, which involves extruding molten polymer through fine nozzles to create continuous filaments that are then laid down in a random pattern onto a moving conveyor belt. The resulting web of fibres is then bonded together using heat, pressure, or chemicals, without the use of weaving or knitting.

Polypropylene spun-bond non woven fabric is made of 100% polypropylene fibre, which is extruded and spun to form a web of randomly-oriented, continuous filaments. The web is then subjected to a thermal bonding process to create a non woven fabric.

Polypropylene spun-bond non woven fabric is a kind of non woven fabric created from polypropylene (PP) yarns. It is created utilizing a procedure which is named the spun-bond procedure, which pertains to extruding molten polymer through fine nozzles to develop endless filaments that are then laid down in a random design onto a moving conveyor belt. The resulting web of yarns is then connected utilizing heat, pressure, or chemicals, without the usage of intertwining or knitting.

When you want to buy this type of bag then always want the best LS Trading is the best and famous player in this field. They also distribute their products outside India and in United States, United Kingdom, Australia, Canada and United Arab Emirates.

Polypropylene Spunbond non-woven fabric is typically made from polypropylene, a type of plastic that is not biodegradable. However, we do manufacturers use biodegradable materials, such as polylactic acid (PLA), to make PP spunbond non-woven fabric supplier.

In general, spunbond non-woven fabric made from polypropylene is not biodegradable and can take hundreds of years to break down in the environment. However, it is recyclable in some cases. On the other hand, PP spunbond nonwoven fabric made from biodegradable materials such as PLA can break down more quickly in the environment. However, it is important to note that biodegradable materials require specific conditions, such as high temperatures and microbial activity, to break down properly.

Features:

- High Strength: It has high tensile strength, tear strength and bursting strength, making it suitable for heavy-duty applications.

- Breathable: The fabric has excellent air permeability, making it breathable and comfortable to wear.

- Water-resistant: It has good water resistance, making it suitable for use in products that are exposed to moisture.

- Chemical-resistant: The fabric is resistant to a wide range of chemicals, making it suitable for use in harsh environments.

- Anti-static: It has anti-static properties, making it suitable for use in electronic and other industries where static electricity is a concern.

- Easy to clean: The fabric is easy to clean and maintain, which makes it suitable for use in products that require frequent washing.

Advantages:

- Lightweight: It is very lightweight, making it easy to handle and transport.

- Softness: This type of fabric is also very soft and comfortable to wear, making it ideal for use in clothing and bedding.

- Cost-effective: It is an affordable alternative to traditional woven fabrics, making it an attractive option for manufacturers looking to reduce costs while maintaining quality.

- Recyclable: The fabric is recyclable, making it an environmentally friendly option.

- Non-toxic: The fabric is non-toxic, making it safe for use in medical and other sensitive applications.

- Medical industry: PP spunbond nonwoven fabric is widely used in the medical industry for manufacturing surgical masks, disposable gowns, drapes, and medical packaging materials.

- Agriculture: It is used for crop protection, greenhouse covering, and soil erosion control. It provides excellent UV resistance and has high water permeability.

- Filtration: It is used in the manufacturing of air and liquid filters. It has excellent filtration properties and can trap fine particles.

- Automotive industry: It is used in the manufacturing of car upholstery, trunk liners, and interior trim.

- Construction industry: It is used for insulation, roofing, and soundproofing.

- Packaging industry: It is used for making reusable bags, packaging materials, and protective covers.

- Home textiles: It is used for making curtains, bed linens, and upholstery.

- Basis weight: This refers to the weight of the fabric per unit area, typically measured in grams per square meter (gsm). The basis weight of polypropylene spunbond nonwoven fabric can range from 10 gsm to over 150 gsm, depending on the application.

- Width: Polypropylene spunbond nonwoven fabric can be produced in various widths, ranging from a few centimeters to several meters wide, depending on the manufacturing process.

- Color: The fabric can be produced in a variety of colors, including white, black, and a range of other colors.

- Tensile strength: This refers to the ability of the fabric to withstand pulling forces. The tensile strength of polypropylene spunbond nonwoven fabric can range from 10 N/5 cm to over 200 N/5 cm, depending on the basis weight and manufacturing process.

- Elongation: This refers to the ability of the fabric to stretch before breaking. The elongation of polypropylene spunbond nonwoven fabric can range from 50% to over 300%, depending on the basis weight and manufacturing process.

- Melt flow rate (MFR): This refers to the rate at which molten polypropylene flows through a capillary under.

Related products

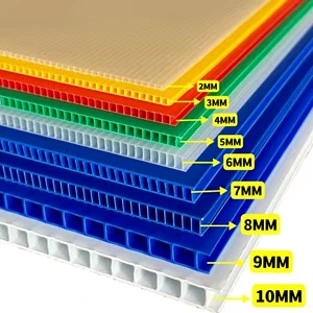

PP Flute Board

- Lightweight and easy to handle: Simplifies transportation and installation.

- High impact strength and durability: Ensures longevity and resistance to damage.

- Water and chemical resistance: Ideal for demanding environments.

- Recyclable and eco-friendly: Supports sustainable practices.

- Excellent printability: Perfect for high-quality signage and advertising.

- Thickness: Ranging from 2mm to 10mm to suit various requirements.

- Sizes: Fully customizable to meet specific project dimensions.

- Colors: A wide range of colors available upon request to match branding or aesthetic needs.

Weed Mat

- Strong, durable and long lasting

- Prevents weeds growth in agriculture farms, nurseries, greenhouses, etc.

- UV resistance

- Boosts plant growth

- Water saving and reduces the use of herbicide

- Durable

- Air and water can pass easily

- Resistance against fungus and tears

- Prevents weed growth

- Strong tensile resistance

- Long term durability

- Prevents erosion

- Regulates temperature

- Soil stabilization

- Prevent grass growing in agricultural farm

- A cheap and appropriate way to prevent weed growth

- Environment friendly

- Non-toxic method to stop the growth of weed compared to chemical weed killer

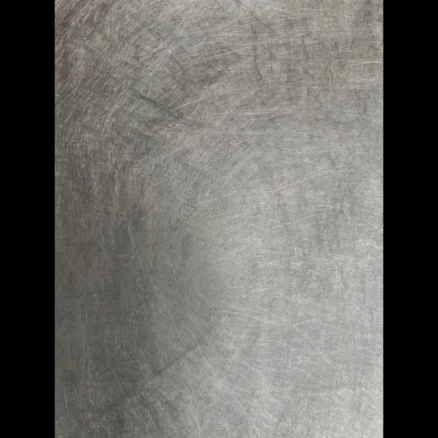

Roofing Underlayment

- Asphalt-saturated felt is described as felt paper and is made from organic; hence it is called an organic underlayment. It is generally applied throughout the roof deck and is recommended considering local weather conditions. It is used in residential and steep slope applications as it is water resistant and not waterproof.

- Rubberized Asphalt is a bit costly compared to the other two underlayments, as it has a good amount of asphalt and rubber polymers to build it waterproof and is more suitable in regions where it is severe winter. Such underlayment is used at Eaves, Valleys, and surfaces with low slope roofs.

- Finally, the most demandable roofing underlayment is roofing underlayment suppliers, also called non-bitumen synthetic underlayment. Synthetic roofing underlayment gives the roof an additional surface of safety that is not possible solely with shingles. It is lightweight and thin compared to asphalt felts. Moreover, the installation process is also very easy. It is a tough, durable, and high strength, designed in such a way that it prevents skidding and improves walkability during installation due to its unique textured fabric. It is resistant to moisture, UV damage, tears, leaks, and fungal growth and is wrinkle-free even when exposed to the elements. It is available in longer and wider rolls; hence it gets fewer trips up the ladder due to fewer rolls.

Our professional and highly experienced quality testing team always ensures that the Roofing Underlayment Exporters, keeping in mind strict measures of quality standards. To maintain the highest quality of the Roof Underlayment and provide the best service to our customers.

Features:- Stop water infiltration

- Extended UV Exposure

- Capture less heat

- Good resistance to water and vapor

- Tear and puncture resistance

- Slip resistance walking surface

- ISO authorized

- Tough and Durable Material

- Extreme weather protection

- Prevent from skidding during installation

- High temperature tolerance

- Water and fire resistant

- Wrinkle-free when exposed to the elements

- Simple and Quick Installation

- It won’t absorb water

- Increase job site productivity due to lighter rolls

- Does not require extra equipment

- Better leak protection

- More flexible in the cold

- Clean and easier to handle

- Enhance walkability and the life of roof due to unique textured fabric

- More coverage per roll

Rockshield Mesh

- Apertures allow water flow

- Wear Resistance

- Corrosion Resistance

- Impact Resistance

- Tear Strength

- Elongation

- Tensile Strength

- Chemically inert

- Restrict geologic movements from damaging pipeline

- Minimizes impact and penetration damage

- Absorbs impact of uneven rock backfill

- Flexible event at sub-zero temperature

- Protects pipe coating from rock backfill

- Reduces abrasion of coating from pipe movement underground

- Protects pipeline during excavations

- Not influence by utmost temperature or wet weather

- Cushions against concrete weights

- Cuts with a utility knife

- Ample weight, thickness and strength protects pipeline

- No mechanical damage during backfilling operations

- Resistance to destructive forces

- Cost-effective alternative to sand collar

- Lightweight, flexible and easy to handle

- Minimizes pipeline coating damage which can cause corrosion

- Easy to install

- Provides pipeline & coating protection at affordable rate

- Maintains effectiveness of cathodic protection

- It will not Rot

- Protects pipe during loading, unloading & transportation

PP Woven Fabric

- High Tensile Strength and Durability: PP woven fabric boasts exceptional tensile strength, making it remarkably durable. This inherent strength ensures that the fabric can withstand considerable stress and pressure without tearing or breaking, enhancing its longevity.

- Heat Resistance: PP woven fabric exhibits a notable resistance to heat, which makes it suitable for applications where exposure to high temperatures is a concern. This characteristic helps maintain the fabric's structural integrity even under challenging conditions.

- Low Elongation: The fabric's low elongation property signifies that it retains its shape and dimensions even when subjected to stretching forces. This feature is essential for maintaining the integrity of the items or materials it encases.

- Improved Stiffness and Rigidity: PP woven fabric offers improved stiffness and rigidity, imparting stability to the items it envelops. This characteristic is especially advantageous for packaging and protecting items that require shape preservation.

- Gravure Printing in Multiple Colors: With the capability to be gravure printed in up to six colors, PP woven fabric allows for vibrant and intricate designs. This quality enhances its aesthetic appeal and branding potential.

- UV Stabilization: The fabric is UV stabilized, which means it can withstand prolonged exposure to sunlight without deteriorating or losing its structural integrity. This makes it suitable for outdoor applications.

- Strong Wear Resistance: PP woven fabric exhibits strong wear resistance, ensuring that it can withstand abrasion and friction without succumbing to damage. This makes it an ideal choice for rugged applications.

- Moisture and Tear-Proof Nature: The fabric's moisture-resistant and tear-proof properties make it reliable for safeguarding items from moisture damage and physical harm, ensuring their protection during transportation and storage.

- Coated and Uncoated Options: PP woven fabric is available in both coated and uncoated variations, providing versatility to cater to specific requirements. Coating options can offer additional attributes such as water resistance or enhanced strength.

- Economical and Eco-Friendly: PP woven fabric is cost-effective to produce and purchase, making it an economical choice for various applications. Furthermore, its recyclable nature aligns with eco-friendly initiatives.

- Long Lasting: The fabric's durability and resistance to wear and tear contribute to its extended lifespan, ensuring that items packaged within it remain protected for extended periods.

- Flexible and Lightweight: Despite its robustness, PP woven fabric retains flexibility and lightweight properties. This combination of features simplifies handling, transportation, and wrapping tasks.

- Recyclable: PP woven fabric is recyclable, promoting sustainability and minimizing environmental impact by reducing waste generation.

- Easy to Carry: The fabric's lightweight nature, along with its flexible characteristics, makes it easy to carry, whether during packaging, transportation, or other applications.

- Versatile Applications: PP woven fabric is utilized for various purposes, including covering items, packaging goods, and wrapping materials, showcasing its adaptability.

Spout Pouch

| Products Details | Classification |

|---|---|

| Bag Style | Stand Up, Flat Bottom, Side Gusset, Shaped Bag |

| Base Material | PET ( Polyester), LDPE, Aluminium |

| Pouch Size | Customized sizes available |

| Pouch Pattern | Plain & Printed |

| Color | Transparent, Single & Multi-Color |

| Thickness | 51 microns onwards |

| Sealing & Handle | Spout Top |

Plastic Carry Bags

-

- Plastic grocery bags: These bags are perfect for packaging and transporting groceries. They are made of clear plastic but partially translucent, and come in various sizes to accommodate objects of varying weights.

-

- Plastic shopping bags: These bags are a popular choice for retail stores and supermarkets. They are convenient for customers to carry their purchases and are often given out for free at the point of sale.

-

- Customized plastic carry bags: We offer custom printing options for our bags, allowing businesses to promote their company name and logo. These bags are perfect for marketing and advertising your business.

-

- Polyethylene Medium Density (MDPE): While not as transparent as Low-density Polyethylene (LDPE), medium-density polyethylene is less transparent than High-Density Polyethylene (HDPE). These bags typically have a higher strength than Plastic carry bag manufacturers but less flexibility. This kind of polyethylene is used on a significantly lesser level than HDPE and is often used for product packaging and disposal bags.

-

- Polyethylene Low Density (LDPE): Another popular polyolefin is low-density polyethylene (LDPE). These materials are either white or transparent when used to make bags. LDPE is frequently selected for consumer packaging when strength is not required, including bags for bread, paper, frozen meals, fresh fruit, clean clothing, etc. The material is transparent and shiny, and the bags used to make it are incredibly stretchable, flexible, and transparent. Additionally, they offer high moisture and wear resistance but only modest gas barrier qualities.

-

- Low-Density Polyethylene Linear (LLDPE): LLDPE or linear low-density polyethylene are similar in their properties and applications. LLDPE is preferred for various applications due to a few differences, though. In contrast to LDPE, which is often chosen for its greater clarity, ease of manufacturing, and better gloss, LLDPE is often chosen for its stronger compressive and impact strength and superior heat seal ability. Grocery, frozen food, waste, daily newspaper, and essential food bags are essential uses.

- Excellent Tensile strength

- Low water absorption

- Low-temperature resistance

- Good chemical stability and heat resistance

- Resistance to most alcohol, acid, and alkali

- Plastic bags are lightweight and thin.

- Flexible and versatile carrier bags

- Plastic Bag Packaging is Strong and Durable

- Plastic bags are a Budget-Friendly Alternative.