Pet Thermo Bonded Fabrics

Polyester Continuous Filament Cover is a synthetic fibre, made up of polyester linear macromolecules generated through the condensation of alcohol and diacid or W-hydroxy acid. Polyethylene terephthalate (PET) is currently used in large-scale industrial polyester fiber manufacture, also known as PET fibre.

Polyester filament is a continuous fibre valued for its durability and adaptability. DTY filament (draw textured yarn) is made from POY (part-oriented yarn) that has been stretched and clamped to add strength, volume, and softness.

Its applications are numerous, but the most popular Pet Thermo Bonded Fabrics include textiles, knits, outfits, apparel items, ribbons, labels, sporting and ornamental products (cushions and duvets), tennis materials, car seats, and even zippers.

Polyester Continuous Filament Cover Material, also referred to as Polyester Filament Fabric or Continuous Filament Polyester. Polyester fabric is commonly made from petroleum. This fabric is highly sought-after and can be used in a variety of ways. The manufacturing of this fabric involves a technique called polymer extrusion. Pet Thermo Bonded Fabrics Supplier is consists primarily of compounds that contain the ester functional group and is classified as a polymer. The majority of synthetic and plant-derived polyester fibres are produced using ethylene, which is a petrochemical component that can also be sourced from other materials.

Features:

● Durability-The fabric has very high durability and is resistant to wear and tear. This makes the fabric long-lasting in adverse conditions.

● Flexibility- It’s easier to handle because of flexibility and various applications.

● Uniform filament structure- It has the proper filament distribution, resulting in increased performance and uniformity.

● Versatility- This fabric is used in various types of industries and commercially.

● Resistance to chemicals- It has a high resistance to chemicals without losing its strength.

Advantages:

● Cost-effective- The material is made with long, continuously long fiber resulting in strength and durability. Because of Pet Thermo Bonded Fabric Manufacturers, it requires less maintenance and replacement, which makes it cost-effective.

● Environment friendly- This material is recyclable and many manufacturers use PET(polyethene terephthalate). This ensures to reduce the environmental effect and decrease the waste.

● customizable- Because of its structure, it can be produced with various thicknesses, weights and according to needs, making this suitable for a wide brand of industries.

Polyester Continuous Filament Cover Material has various applications in different industries.

● Automobile industry- In automobiles it is used for interior linings such as seat covers, headrests and door panels. Because of Pet Thermo Bonded Fabrics Supplier durability, it is the ideal product to use in daily rigors use.

● Packing- For the packing industry, it is used for protective covers and packing solutions. It helps to secure the packing during transportation without any damage.

● Construction- For strengthening building and infrastructure material. This is used to make geotextiles and protective gears.

● Textile manufacturing- For composite fabrics and the textile industry and because of the structure, it is ideal for the coating and bonding process.

● For Apparel- The material is also used for shirts, pants, suits, jackets, etc.

● For homeware- In homeware, it is used for bath and kitchen towels and it is also used in cushions, pillows and curtains.

● Industrial application- In industrial application, it is used in LCDs, holographic display film and boats.

● Outdoor equipment- The material durability and strength make this perfect for outdoor equipment. Because of its durability, it can be used for extreme weather conditions and long exposure to UV rays. These are ideal materials to use to make

tents or other outdoor equipment.

● Material- Polyester Continuous Filament.

● Width- Available as per requirement and application.

● Weight- Depends on the application and is adjustable according to thickness and durability.

● Color- Available in multiple colors or requirements and with dying options.

● Packing- Custom packing or Requirement

Related products

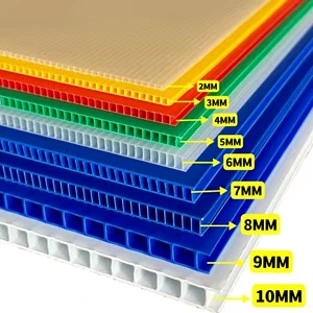

PP Flute Board

- Lightweight and easy to handle: Simplifies transportation and installation.

- High impact strength and durability: Ensures longevity and resistance to damage.

- Water and chemical resistance: Ideal for demanding environments.

- Recyclable and eco-friendly: Supports sustainable practices.

- Excellent printability: Perfect for high-quality signage and advertising.

- Thickness: Ranging from 2mm to 10mm to suit various requirements.

- Sizes: Fully customizable to meet specific project dimensions.

- Colors: A wide range of colors available upon request to match branding or aesthetic needs.

Silt Fence

- Makes a physical boundary around the site

- UV stable dark fence texture

- Logo printing accessible

- Keep mud off roads and neighboring property

- Straightforward plan and straightforward establishment

- Ensure streams

- Holds silt on the place of work

- Channels overflow before leaving the site

- Assists with forestalling disintegration

- Accessible with or without stakes

- Preassembled fence with presents joined on texture

- Marker line on texture shows anchor profundity

- Forestall exorbitant place of work materials from depleting off

- Keep streets and streams liberated from contamination

- Light to medium quality woven textures

- Steel backing is likewise accessible for improved execution

- Endorsed for DOT use in numerous states

- Shield residue from leaving building locales

Weed Mat

- Strong, durable and long lasting

- Prevents weeds growth in agriculture farms, nurseries, greenhouses, etc.

- UV resistance

- Boosts plant growth

- Water saving and reduces the use of herbicide

- Durable

- Air and water can pass easily

- Resistance against fungus and tears

- Prevents weed growth

- Strong tensile resistance

- Long term durability

- Prevents erosion

- Regulates temperature

- Soil stabilization

- Prevent grass growing in agricultural farm

- A cheap and appropriate way to prevent weed growth

- Environment friendly

- Non-toxic method to stop the growth of weed compared to chemical weed killer

Roofing Underlayment

- Asphalt-saturated felt is described as felt paper and is made from organic; hence it is called an organic underlayment. It is generally applied throughout the roof deck and is recommended considering local weather conditions. It is used in residential and steep slope applications as it is water resistant and not waterproof.

- Rubberized Asphalt is a bit costly compared to the other two underlayments, as it has a good amount of asphalt and rubber polymers to build it waterproof and is more suitable in regions where it is severe winter. Such underlayment is used at Eaves, Valleys, and surfaces with low slope roofs.

- Finally, the most demandable roofing underlayment is roofing underlayment suppliers, also called non-bitumen synthetic underlayment. Synthetic roofing underlayment gives the roof an additional surface of safety that is not possible solely with shingles. It is lightweight and thin compared to asphalt felts. Moreover, the installation process is also very easy. It is a tough, durable, and high strength, designed in such a way that it prevents skidding and improves walkability during installation due to its unique textured fabric. It is resistant to moisture, UV damage, tears, leaks, and fungal growth and is wrinkle-free even when exposed to the elements. It is available in longer and wider rolls; hence it gets fewer trips up the ladder due to fewer rolls.

Our professional and highly experienced quality testing team always ensures that the Roofing Underlayment Exporters, keeping in mind strict measures of quality standards. To maintain the highest quality of the Roof Underlayment and provide the best service to our customers.

Features:- Stop water infiltration

- Extended UV Exposure

- Capture less heat

- Good resistance to water and vapor

- Tear and puncture resistance

- Slip resistance walking surface

- ISO authorized

- Tough and Durable Material

- Extreme weather protection

- Prevent from skidding during installation

- High temperature tolerance

- Water and fire resistant

- Wrinkle-free when exposed to the elements

- Simple and Quick Installation

- It won’t absorb water

- Increase job site productivity due to lighter rolls

- Does not require extra equipment

- Better leak protection

- More flexible in the cold

- Clean and easier to handle

- Enhance walkability and the life of roof due to unique textured fabric

- More coverage per roll

Plastic Tree Guard

- UV protection.

- Protection from animals and bugs.

- Protection from wind damage.

- Protection from trampling/physical damage.

- Weed control.

- Made from recycled plastic

- Creates an ideal microclimate for young plant growth

- UV stabilized

- Scientifically proven to produce the best plant growth results

- Economical and cost-effective for large plantings

- Protects against spray drift and small animals

- Reusable for multiple planting seasons

- Common Sources of Tree Trunk Injury

- Rabbits and mice (like mice)

- Sun in the winter (sunscald, trunk splitting, etc.)

Plastic Carry Bags

-

- Plastic grocery bags: These bags are perfect for packaging and transporting groceries. They are made of clear plastic but partially translucent, and come in various sizes to accommodate objects of varying weights.

-

- Plastic shopping bags: These bags are a popular choice for retail stores and supermarkets. They are convenient for customers to carry their purchases and are often given out for free at the point of sale.

-

- Customized plastic carry bags: We offer custom printing options for our bags, allowing businesses to promote their company name and logo. These bags are perfect for marketing and advertising your business.

-

- Polyethylene Medium Density (MDPE): While not as transparent as Low-density Polyethylene (LDPE), medium-density polyethylene is less transparent than High-Density Polyethylene (HDPE). These bags typically have a higher strength than Plastic carry bag manufacturers but less flexibility. This kind of polyethylene is used on a significantly lesser level than HDPE and is often used for product packaging and disposal bags.

-

- Polyethylene Low Density (LDPE): Another popular polyolefin is low-density polyethylene (LDPE). These materials are either white or transparent when used to make bags. LDPE is frequently selected for consumer packaging when strength is not required, including bags for bread, paper, frozen meals, fresh fruit, clean clothing, etc. The material is transparent and shiny, and the bags used to make it are incredibly stretchable, flexible, and transparent. Additionally, they offer high moisture and wear resistance but only modest gas barrier qualities.

-

- Low-Density Polyethylene Linear (LLDPE): LLDPE or linear low-density polyethylene are similar in their properties and applications. LLDPE is preferred for various applications due to a few differences, though. In contrast to LDPE, which is often chosen for its greater clarity, ease of manufacturing, and better gloss, LLDPE is often chosen for its stronger compressive and impact strength and superior heat seal ability. Grocery, frozen food, waste, daily newspaper, and essential food bags are essential uses.

- Excellent Tensile strength

- Low water absorption

- Low-temperature resistance

- Good chemical stability and heat resistance

- Resistance to most alcohol, acid, and alkali

- Plastic bags are lightweight and thin.

- Flexible and versatile carrier bags

- Plastic Bag Packaging is Strong and Durable

- Plastic bags are a Budget-Friendly Alternative.

HDPE Duct Spacer

- Material: HDPE Duct Spacer is made from high-density polyethylene (HDPE), which is known for its excellent strength, durability, and resistance to environmental factors like UV rays, chemicals, and moisture.

- Design: The spacer is designed to maintain a constant separation between multiple conduits or ducts, which reduces the risk of damage from external factors like soil movement, seismic activity, and traffic loads. It also prevents friction between the conduits, reducing the risk of damage caused by rubbing.

- Easy Installation: The spacer is designed for easy installation, with most models featuring snap-on or clip-on designs that allow them to be easily installed and removed without the need for specialized tools.

- Longevity: Duct Bank Spacer has a long service life and requires minimal maintenance, making it a cost-effective solution for conduit installations.

- Durability: It is made from a high-density polyethylene material, which is known for its strength and durability. This material is resistant to impact, abrasion, and weathering, making it ideal for use in harsh environments.

- Corrosion Resistance: HDPE Duct Spacer is highly resistant to corrosion, which makes it an ideal material for use in underground and overhead installations.

- Easy Installation: It is designed for easy installation, with most models featuring snap-on or clip-on designs that allow them to be easily installed and removed without the need for specialized tools.

- Versatility: HDPE Duct Spacer is available in a variety of shapes, sizes, and configurations to suit different conduit arrangements. Some designs allow for easy adjustment of spacing between the conduits, while others provide a more permanent solution.

- Cost-effective: It is a cost-effective solution for maintaining separation between multiple conduits and ducts, protecting them from damage, and ensuring the longevity and reliability of conduit systems.

- Environmentally friendly: HDPE Duct Spacer is an environmentally friendly material, as it is made from a non-toxic and recyclable material.

HDPE Duct Coupler

Using a PE (polyethylene) duct coupler supplier is a relatively simple process that can be done with a few basic tools. Here are the steps to follow:

- First, ensure that the ends of the ducting or pipe that you want to connect with the coupler are clean and free of debris or rough edges.

- Slide the PE duct coupler over one end of the ducting or pipe until it reaches the center of the coupler. Make sure that the coupler is aligned properly with the end of the ducting or pipe.

- Repeat step 2 with the other end of the ducting or pipe, sliding it into the other side of the duct coupler price until it reaches the center.

- Use a wrench or pliers to tighten the coupler's grip on both ends of the ducting or pipe. This will ensure a tight and secure connection.

- If necessary, use a sealant or adhesive to create an airtight or watertight seal between the ducting or pipe and the coupler.

- Finally, test the connection to ensure that it is secure and leak-free.

- High Strength: HDPE duct couplers are made from high-density polyethylene, which is a strong and durable material. This means that they are able to withstand heavy loads and pressures, making them ideal for use in underground applications.

- Chemical Resistance: HDPE is highly resistant to a wide range of chemicals, including acids, alkalis, and solvents. This makes it ideal for use in industries where exposure to harsh chemicals is common.

- UV Resistance: HDPE duct couplers are also highly resistant to UV radiation, which can cause other materials to degrade and break down over time. This makes HDPE an ideal choice for outdoor applications where exposure to sunlight is a concern.

- Corrosion Resistance: Unlike metal couplers, HDPE duct couplers are highly resistant to corrosion. This makes them ideal for use in underground applications where moisture and soil can cause metal components to rust and deteriorate over time.

- Flexibility: HDPE is a flexible material, which means that it can bend and flex without breaking. This makes HDPE duct couplers ideal for use in applications where flexibility is a concern, such as in telecommunications and electrical conduits.

- Easy Installation: HDPE duct couplers are easy to install and require no special tools or equipment. They can be installed quickly and easily by one person, which can save time and money on installation costs.

- Leak-Free: HDPE duct couplers are designed to create a tight, leak-free seal between two or more sections of ductwork. This helps to prevent leaks and other issues that can cause damage to underground utilities and infrastructure.

- Wide Range of Sizes: HDPE duct couplers are available in a wide range of sizes, from small diameters of 20mm up to large diameters of 630mm or more. This makes them suitable for use in a variety of applications, from residential and commercial plumbing to large-scale industrial piping systems.

- Durability: HDPE duct couplers are made from high-density polyethylene, which is a durable and long-lasting material. This means that they are able to withstand heavy loads and pressures, making them ideal for use in underground applications.

- High Strength: HDPE duct couplers are made from high-density polyethylene, which is a strong and durable material. This means that they are able to withstand heavy loads and pressures, making them ideal for use in underground applications.

- Easy Installation: HDPE duct couplers are easy to install and require no special tools or equipment. They can be installed quickly and easily by one person, which can save time and money on installation costs.

- Low Maintenance: HDPE duct couplers require very little maintenance and are designed to last for many years without the need for replacement or repairs. This can help to reduce maintenance costs and downtime for businesses and organizations.