Material For Infrastructure Works

HDPE Duct Coupler

LS Trading manufacturer, exporter & supplier of HDPE Duct Coupler. A PE duct coupler, also known as a polyethylene duct coupler, is a type of fitting that is used to connect two pieces of polyethylene ductwork. Polyethylene ductwork is a popular choice for underground ducting and piping applications due to its flexibility, durability, and resistance to corrosion.

PE duct couplers are typically made from high-density polyethylene (HDPE) material, which is known for its high strength and resistance to abrasion, chemicals, and weathering. They are available in a range of sizes, ranging from small diameters of 20mm up to large diameters of 630mm or more.

HDPE duct coupler are designed to connect two pieces of polyethylene ductwork together in a secure and leak-free manner. They have a simple design consisting of two cylindrical pieces, one of which has a slightly larger diameter than the other. The larger piece is inserted over the end of one piece of ductwork, while the smaller piece is inserted over the end of the other piece of ductwork. The two pieces are then pushed together and secured in place with a locking mechanism, typically a clamp or a compression fitting.

Using a PE (polyethylene) duct coupler supplier is a relatively simple process that can be done with a few basic tools. Here are the steps to follow:

- First, ensure that the ends of the ducting or pipe that you want to connect with the coupler are clean and free of debris or rough edges.

- Slide the PE duct coupler over one end of the ducting or pipe until it reaches the center of the coupler. Make sure that the coupler is aligned properly with the end of the ducting or pipe.

- Repeat step 2 with the other end of the ducting or pipe, sliding it into the other side of the duct coupler price until it reaches the center.

- Use a wrench or pliers to tighten the coupler's grip on both ends of the ducting or pipe. This will ensure a tight and secure connection.

- If necessary, use a sealant or adhesive to create an airtight or watertight seal between the ducting or pipe and the coupler.

- Finally, test the connection to ensure that it is secure and leak-free.

- High Strength: HDPE duct couplers are made from high-density polyethylene, which is a strong and durable material. This means that they are able to withstand heavy loads and pressures, making them ideal for use in underground applications.

- Chemical Resistance: HDPE is highly resistant to a wide range of chemicals, including acids, alkalis, and solvents. This makes it ideal for use in industries where exposure to harsh chemicals is common.

- UV Resistance: HDPE duct couplers are also highly resistant to UV radiation, which can cause other materials to degrade and break down over time. This makes HDPE an ideal choice for outdoor applications where exposure to sunlight is a concern.

- Corrosion Resistance: Unlike metal couplers, HDPE duct couplers are highly resistant to corrosion. This makes them ideal for use in underground applications where moisture and soil can cause metal components to rust and deteriorate over time.

- Flexibility: HDPE is a flexible material, which means that it can bend and flex without breaking. This makes HDPE duct couplers ideal for use in applications where flexibility is a concern, such as in telecommunications and electrical conduits.

- Easy Installation: HDPE duct couplers are easy to install and require no special tools or equipment. They can be installed quickly and easily by one person, which can save time and money on installation costs.

- Leak-Free: HDPE duct couplers are designed to create a tight, leak-free seal between two or more sections of ductwork. This helps to prevent leaks and other issues that can cause damage to underground utilities and infrastructure.

- Wide Range of Sizes: HDPE duct couplers are available in a wide range of sizes, from small diameters of 20mm up to large diameters of 630mm or more. This makes them suitable for use in a variety of applications, from residential and commercial plumbing to large-scale industrial piping systems.

- Durability: HDPE duct couplers are made from high-density polyethylene, which is a durable and long-lasting material. This means that they are able to withstand heavy loads and pressures, making them ideal for use in underground applications.

- High Strength: HDPE duct couplers are made from high-density polyethylene, which is a strong and durable material. This means that they are able to withstand heavy loads and pressures, making them ideal for use in underground applications.

- Easy Installation: HDPE duct couplers are easy to install and require no special tools or equipment. They can be installed quickly and easily by one person, which can save time and money on installation costs.

- Low Maintenance: HDPE duct couplers require very little maintenance and are designed to last for many years without the need for replacement or repairs. This can help to reduce maintenance costs and downtime for businesses and organizations.

PP Spunbond Nonwoven Fabric

Polypropylene spun-bond non woven fabric is a type of non woven material made from polypropylene (PP) fibres. It is produced using a process called spun-bond technology, which involves extruding molten polymer through fine nozzles to create continuous filaments that are then laid down in a random pattern onto a moving conveyor belt. The resulting web of fibres is then bonded together using heat, pressure, or chemicals, without the use of weaving or knitting.

Polypropylene spun-bond non woven fabric is made of 100% polypropylene fibre, which is extruded and spun to form a web of randomly-oriented, continuous filaments. The web is then subjected to a thermal bonding process to create a non woven fabric.

Polypropylene spun-bond non woven fabric is a kind of non woven fabric created from polypropylene (PP) yarns. It is created utilizing a procedure which is named the spun-bond procedure, which pertains to extruding molten polymer through fine nozzles to develop endless filaments that are then laid down in a random design onto a moving conveyor belt. The resulting web of yarns is then connected utilizing heat, pressure, or chemicals, without the usage of intertwining or knitting.

When you want to buy this type of bag then always want the best LS Trading is the best and famous player in this field. They also distribute their products outside India and in United States, United Kingdom, Australia, Canada and United Arab Emirates.

Polypropylene Spunbond non-woven fabric is typically made from polypropylene, a type of plastic that is not biodegradable. However, we do manufacturers use biodegradable materials, such as polylactic acid (PLA), to make PP spunbond non-woven fabric supplier.

In general, spunbond non-woven fabric made from polypropylene is not biodegradable and can take hundreds of years to break down in the environment. However, it is recyclable in some cases. On the other hand, PP spunbond nonwoven fabric made from biodegradable materials such as PLA can break down more quickly in the environment. However, it is important to note that biodegradable materials require specific conditions, such as high temperatures and microbial activity, to break down properly.

Features:

- High Strength: It has high tensile strength, tear strength and bursting strength, making it suitable for heavy-duty applications.

- Breathable: The fabric has excellent air permeability, making it breathable and comfortable to wear.

- Water-resistant: It has good water resistance, making it suitable for use in products that are exposed to moisture.

- Chemical-resistant: The fabric is resistant to a wide range of chemicals, making it suitable for use in harsh environments.

- Anti-static: It has anti-static properties, making it suitable for use in electronic and other industries where static electricity is a concern.

- Easy to clean: The fabric is easy to clean and maintain, which makes it suitable for use in products that require frequent washing.

- Lightweight: It is very lightweight, making it easy to handle and transport.

- Softness: This type of fabric is also very soft and comfortable to wear, making it ideal for use in clothing and bedding.

- Cost-effective: It is an affordable alternative to traditional woven fabrics, making it an attractive option for manufacturers looking to reduce costs while maintaining quality.

- Recyclable: The fabric is recyclable, making it an environmentally friendly option.

- Non-toxic: The fabric is non-toxic, making it safe for use in medical and other sensitive applications.

Pet Thermo Bonded Fabrics

Polyester Continuous Filament Cover is a synthetic fibre, made up of polyester linear macromolecules generated through the condensation of alcohol and diacid or W-hydroxy acid. Polyethylene terephthalate (PET) is currently used in large-scale industrial polyester fiber manufacture, also known as PET fibre.

Polyester filament is a continuous fibre valued for its durability and adaptability. DTY filament (draw textured yarn) is made from POY (part-oriented yarn) that has been stretched and clamped to add strength, volume, and softness.

Its applications are numerous, but the most popular Pet Thermo Bonded Fabrics include textiles, knits, outfits, apparel items, ribbons, labels, sporting and ornamental products (cushions and duvets), tennis materials, car seats, and even zippers.

Polyester Continuous Filament Cover Material, also referred to as Polyester Filament Fabric or Continuous Filament Polyester. Polyester fabric is commonly made from petroleum. This fabric is highly sought-after and can be used in a variety of ways. The manufacturing of this fabric involves a technique called polymer extrusion. Pet Thermo Bonded Fabrics Supplier is consists primarily of compounds that contain the ester functional group and is classified as a polymer. The majority of synthetic and plant-derived polyester fibres are produced using ethylene, which is a petrochemical component that can also be sourced from other materials.

Features:

● Durability-The fabric has very high durability and is resistant to wear and tear. This makes the fabric long-lasting in adverse conditions.

● Flexibility- It’s easier to handle because of flexibility and various applications.

● Uniform filament structure- It has the proper filament distribution, resulting in increased performance and uniformity.

● Versatility- This fabric is used in various types of industries and commercially.

● Resistance to chemicals- It has a high resistance to chemicals without losing its strength.

Advantages:

● Cost-effective- The material is made with long, continuously long fiber resulting in strength and durability. Because of Pet Thermo Bonded Fabric Manufacturers, it requires less maintenance and replacement, which makes it cost-effective.

● Environment friendly- This material is recyclable and many manufacturers use PET(polyethene terephthalate). This ensures to reduce the environmental effect and decrease the waste.

● customizable- Because of its structure, it can be produced with various thicknesses, weights and according to needs, making this suitable for a wide brand of industries.

Geocell

LS Trading, a renowned HDPE Geocell manufacturer, exports premium-quality, durable geocells for optimal soil stabilization and landfill site. We export our products worldwide including the USA, United Kingdom, United Arab Emirates, Australia, and Gulf Countries. Call us or enquire about Geocell Price Now.

LS Trading is the best Geocell Manufacturer worldwide. We always produce the best quality products by keeping the Customer’s needs in mind. You can always trust our products as we have a team of industry experts who always strive hard to provide an excellent product.

With every passing day, the world is upgrading itself. As technology is constantly developing, there's no way out except to adopt it in every utilization. In the modern era, construction has taken a prominent part which can't be progressed without implementing the right technological solution. Here comes the significance of employing a geocell solution! This one of robust technology is primarily used for earth stabilization.

Alternatively known as Cellular Confinement Solutions, the revolutionary honeycomb matrices are vastly applied in many infrastructure projects. Besides soil reinforcement, this modern technology is reliable for enhancing the drainage system. Since 1970, it has been applied to military roads in hilly regions for the utmost stabilization of the earth. You often see this high-duty solution in constructing railways and highways in various corners of the world. To protect steep slopes, there's no better alternative to Geocell solutions. If you deeply research modern engineering methods, it will be clear that this hi-tech solution is the best means for earth protection.

Geocells are used for ground improvement while constructing temporary and permanent roads. The porous and granular surfaces made by Geocells increase the load-bearing magnitude of roads and minimize construction costs.

To protect unpaved roadways on soft soil, Geocells are the ultimate solution that provides rigidity and resistance to deformation. They also make hindrance against shrinking in clay, alleviate lateral dispersion, and strengthen the sub-grade soft soils. In preserved terrain, parking surfaces are covered with vegetation to impact the environment positively.

Maintaining roads with Geocell reinforcement systems keeps them in proper condition. Roads are more likely to experience frequent issues due to weakening characteristics of subsoil, which result in dents, rutting, washing out, and damage to unpaved surfaces. Besides roadways, local forestry, Parish surfaces, fire escape routes, and other places can be improved by employing Geocells.

Geocells are often filled with soil, sand, or gravel to create a strong foundation for roads, parking lots, and other paved surfaces. They can also be filled with lighter materials, such as wood chips or straw, for landscaping projects. Geocells are versatile and can be adapted to a variety of needs.

Features:

- Used as load transferring platform

- Effective in soil stabilizing

- Lightweight yet very strong

- Made of virgin HDPE Material

- High strength

- Installation very easy

- Versatile solutions for roads and highways

- Proven 3d Geocells for soil stability challenges

- Transforms Infill unlike any other Geosynthetics

- Makes soil strong - Confines and stabilizes soils

- The engineered solution to meet any design challenge

- Lowers the cost

- Effortless deployment

- Lifelong performance

- Flexible and permeable

- This is very cost-effective for building unpaved roadways

- Solving many engineering, infrastructure, and construction challenges

- Improve shear strength of granular soil

- Prevent erosion problems

- Solved unacceptable road problems

- Geocell used for Slope Protection

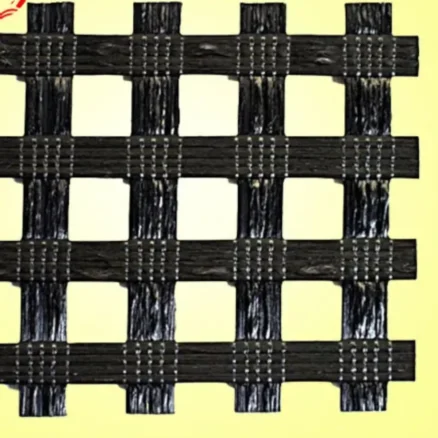

Biaxial Geogrid Manufacturer and Supplier

At LS Trading, we are one of the best manufacturers and exporters of premium quality Biaxial Geogrid Manufacturers. Our manufactured PP Geogrids are specially designed for reinforcement. They possess high tensile strength and have a good capacity for bearing and diffusing load. Biaxial Geogrids manufactured by us is prepared for support and used for various utilities such as slopes, base reinforcement, asphalt overlay, pavement reinforcement, subgrade improvement, and walls.

We live in a world that is becoming more technologically developed; technological upgrades are required to be made in construction. Sometimes, these inventions can make the layout more convenient and quicker. Singhal Industries Private Limited is a Biaxial Geogrid manufacturer in India and exporter to USA, UK, UAE & entire world. We manufacture the Geogrid, which offers a creative building material that minimizes labor and time when creating buildings. Time is money when it comes to construction. Every contractor wants to complete the project quickly so they can start a new project, and Biaxial Geogrid can help them. LS Trading has formulated and patented geogrid, which eradicates the necessity for constructing concrete slabs or bricks.

Biaxial Geogrid supplier India is a polymeric material comprised of numerous polymers like polyethylene, polyvinyl liquor, polypropylene, etc. It is one of the most significant creations in geosynthetics which is utilized as a strengthening material. They are framed by joining converging ribs and have huge open spaces in the middle of the ribs known as "openings." Biaxial Geogrids can be arranged into two layers depending on the pressure move or bearing extending during production as – PP Geogrid – It is extended and developed distinctly along the longitudinal course. In this manner, the pressure is moved uniquely along that pivot; even the rigidity is more longitudinal, contrasted with cross overbearing. Biaxial Geogrid is extended along with two bearings (longitudinal and cross-over). Subsequently, the pressure is similarly appropriated along with the two headings.

You can install the Geogrids as per your requirement as they can be installed underneath the soils of various structure projects to prevent deformation affected by subsidence growing over time. Below are the some of its Examples:

- Porches

- Driveways

- Barricade

- Railroads

- Airport Runways

- Car Parks

- Construction Haulage Roads

- High intersection quality and firmness

- High elasticity at low extension

- Low inclination to crawl

- Simple to introduce, protection from establishment harm

- High synthetic and natural opposition

- Streamlined framework structure and proficient rib profile for expelled Geogrids

- Magnificent draw-out and interface grinding conduct

- Unrivaled association limit with secluded squares

- Protection from ecological pressure breaking

- Effortlessly associated together on location

- Advance soil adjustment

- Give a higher burden-bearing limit

- Adaptable in nature and are notable for their flexibility

- Have high toughness, which diminishes support cost

- They are profoundly impervious to natural impacts

- Anything but difficult to introduce which brings about quicker development

- The simplicity of Construction: PP Biaxial Geogrid can be introduced in any climate conditions, making it all the more requesting

- Land Optimization: This strategy for Geogrid establishment in soils makes an inadmissible zone reasonable for setting it up to meet wanted properties for development. Geogrid, in this way, helps inappropriate land usage

- It is a decent solution for holding soil from disintegration

- No trouble in material accessibility

- Known for their excellent flexibility

- Possess high toughness, diminishing upkeep cost. It is profoundly safe against natural impacts.

- Materials are tried dependent on standard codes and guidelines

Geo Bags – Geotextile bags

Versatile Geotextile Solution for Various Applications

Are you in need of high-quality Geo Bags for your geotechnical engineering projects? Look no further! At LS Trading, we take pride in being a premier manufacturer and exporter of top-notch Geo Bags that cater to a wide range of applications. Whether you’re working on beach protection or flood protection projects, our Geo Bags offer the perfect solution.

LS Trading With years of hands-on experience in the field, we take pride in offering a diverse range of packaging solutions perfectly suited to your unique needs. Our specialized Geo Bags have proven to be invaluable for tackling soil erosion, safeguarding riverbanks, and providing effective flood barriers. What sets us apart is our commitment to tailoring solutions that significantly enhance your overall infrastructure.

Geo Bags, also known as Geotextile Sand Containers (GSC) or sandbags, are true chameleons in the realm of industrial solutions. Across the globe, various industries rely on the unmatched versatility of these multifunctional bags to address a wide array of project requirements. Crafted from highly absorbent fabrics, these bags possess an exceptional capability to preserve, segregate, and fortify.

The significance of Geo Bags extends to environmental engineering and geotechnical constructions. Their stability is so remarkable that they have become a cornerstone in these fields. Primarily devised for the storage and transportation of fertilizers, soil, rocks, sediments, and other solid materials, these bags boast outstanding resistance against abrasion and puncture. This attribute positions them as the ideal choice for effectively separating grains and water, particularly in scenarios where safeguarding against liquid infiltration is paramount.

Geo Bags offer a comprehensive solution that encompasses durability, adaptability, and reliable performance. Our expertise in delivering tailored packaging solutions ensures that your specific infrastructure needs are not only met but exceeded. Join the league of smart industries and professionals who have harnessed the power of Geo Bags to revolutionize soil erosion control, riverbank preservation, and flood management. Your journey towards a more secure and resilient future starts with these exceptional geotextile bags.

These bags comprise a protection layer that raises UV resistance and also gives protection against any damage. Normally, GEO Textiles bags suppliers are soil containers that are in the form of bags made up of geotextile woven or nonwoven fabric.

It is also known as:-

- Geo Bag

- Geotextile Bag

- Non-Woven/Woven Geo Bag

- Geotextile Sand Container

- Sand Bags

- These bags are considered flexible and cost-effective solutions for the construction off-shore protection structures.

- These bags come with excellent durability and robust strength.

- The market is filled with various sizes and strengths of geo bags best suited for specific applications.

- Compared to the traditional marine protection stuff, geo bags are a highly accessible and feasible option.

- There's a high demand for geotextile bags across the different infrastructure projects for their reduced carbon footprint and minimal environmental effect.

- With the proper usage of geo bags, soli susceptible to erosion get transformed into defiant erosion sites.

- These bags are so versatile that they can be used for diversifying situations.

- In comparison to the expensive method of erosion prevention, the Geo sandbag is the most economical alternative.

- The design used in manufacturing geo bags guarantees longevity.

- The geo bags are environment-friendly, and it doesn't negatively impact the environment and abruptly reduce the harmful carbon footprint and disturbance in the site.

- Installing these geotechnical bags is so convenient that it reduces time and cost.

- The advanced mechanical and filtration ensures enhanced usage and maximum efficiency.

- The efficient usage of geotextile bags enhances the speed of construction sites, thus achieving the desired results.

- Ideal solution for coastal, off-shore, and waterfront structures that requires specific protection

Geotextile – Geotextile fabric – Geotextile Sheet – Geotextiles

We, LS Trading are one of the leading and well-known manufacturers offering premium quality Geotextile Fabric, produced with advanced technology. We are also an exporter to the USA, UAE, UK, Australia, and Gulf countries. Geo textile fabric is also known as geosynthetics stabilization fabric. It is made up of permeable synthetic polymer material to produce the latest and modern way of geotextiles.

Geotextile Sheet is manufactured with an aim to improve and maintain soil stability mainly for agriculture and conservation purpose. This geotextile fabric is different from weed cloth. The purpose of weed cloth is to stop the unwanted growth of weeds, whereas geo textile fabric is the best solution for the stabilization of soil on any construction site. It also helps to stop erosion due to stormwater. Moreover, it offers very good results for separation, filtration, reinforcement, and drainage.

Geotextile Fabric For Waterproofing stands out as an exceptional eco-friendly solution. It has very good features like waterproofing, low water flow rate, high tensile strength, etc. It is used in many applications like building construction, civil engineering project, airport runways, water conservancy, petrochemical, landfill drainage, railway embankment, retention pool, salt industry, agriculture, etc. Due to its excellent physical properties and mechanical strength, its lifespan is more than a hundred years.

Geotextile fabric uses: It is a type of synthetic fabric that is often used in construction and engineering projects. It is usually made from polypropylene or polyester and is used to improve the stability and drainage of the soil. Geotextile Sheet for Road Work is often used to reinforce retaining walls, stabilize roadways, and improve drainage in agricultural and landscaping applications. It can also be used to filter sediment from water or to protect fragile ecosystems from the effects of construction or other human activity.

Features:

- Resistance to UV exposure

- High tensile strength

- Soil separation and drainage

- High durability

- Good physical and hydraulic properties

- Low elongation

- Resistant to rot and degradation

- Resistant to biological organisms

- Uses heavy multifilament

- Excellent support to large rock overlays

- Good support under the roadways

- Strengthens soil

- Controls erosion of any area

- Decreases structural failure

- Reduces maintenance costs

- Easy installation

- Versatile and practical in usage

- Improves performance

- Cost-effective and economical

- Made with strong fibers

- Tightly Woven

Geomembrane Sheet

Our innovative product is meticulously engineered to withstand exposure to microorganisms, ultraviolet light, and ozone present in soil environments. The specially formulated Geomembrane we manufacture combines a variety of properties, making it highly versatile for a wide range of geotechnical applications and designs. These HDPE Geomembrane Sheet are particularly designed to excel in water retention and containment scenarios. We take great care to ensure that our Geomembranes boast exceptional welding capabilities, ensuring quick and trouble-free installations. Thanks to their expert engineering, they exhibit remarkable durability, unparalleled flexibility, and formidable protection against punctures, abrasion, and impacts. Our manufacturing processes encompass both factory-based and on-site methods for joining geosynthetic lining materials, each of which adheres to stringent quality-control measures.

Geomembrane suppliers, LS Trading are Provided top-tier High-Density Polyethylene (HDPE), a polymeric material renowned for its superior properties.

Geomembrane is basically used in many civil projects as it works as a flat sheet designed for controlling migration of fluids and soils. Keeping in mind the set international quality standards, our Geomembrane Sheet Manufacturer using premium quality High Density Polypropylene material. This High-Density Polyethylene (HDPE) Geomembrane, offered in various sizes, finishes, and thicknesses based on individual requirements, stands as a cost-effective solution for our clients.

Features:

- Texture and Finish Options: The HDPE geomembrane liner is available in both textured and smooth finishes, providing adaptability to different usage scenarios.

- Temperature Conductivity: Remarkably conductive in high-temperature variations, making it suitable for applications requiring thermal stability.

- Chemical Resistance: Possesses excellent resistance to a wide range of chemicals, enhancing its usability in challenging industrial and environmental settings.

- UV Protection: Offers a reliable ultraviolet protection shield, making it suitable for outdoor applications where exposure to sunlight is prevalent.

- Weather Durability: The geomembrane sheet exhibits exceptional age resistance against the intense stresses of weather, maintaining its integrity over time.

- Welding and Molding: Designed for easy welding and molding, allowing for convenient installation and customization according to project requirements.

- UV Stabilization: Manufactured using UV stabilizers, which enhance its weather resistance capacity and overall longevity.

- Puncture and Water Resistance: Demonstrates high puncture resistance, making it adept at withstanding mechanical stress, and exhibits outstanding water resistance.

- Tensile Strength: Boasts high tensile strength, contributing to its robustness and ability to withstand various mechanical forces.

- Longevity: Designed for long-term use, the geomembrane liner offers extended service life standards, minimizing the need for frequent replacements.

- Roll Format: Supplied in wide rolls for efficient handling and application, available with single or double-sided textured surfaces.

- Easy Installation: The geomembrane's user-friendly design allows for straightforward installation processes.

- Versatile Applications: It finds applications in diverse fields, ranging from waste management and water containment to waterproofing structures.

- Environmental Protection: Utilized in waste and water management, it contributes to environmental conservation by preventing leaks and contaminations.

- Thermal Aging Resistance: Its resistance to thermal aging ensures reliability and effectiveness over the long term.

- Non-Toxic: Made from non-toxic materials, the geomembrane poses no harm to the environment or human health.

- Chemical Resilience: Exhibits resilience against numerous chemical agents, expanding its applicability in various industrial settings.

- Cost-Effective: The geomembrane offers an economical and cost-effective solution for lining requirements, reducing overall project expenses.

- Mechanical Strength: Its impact and tear resistance, along with excellent flexibility, contribute to its robustness and adaptability.

- Reliable Soldering: The geomembrane's superior soldering ability ensures secure joints and a dependable containment system.

- Efficient Transport: Designed for easy transport due to its roll format, facilitating convenient logistics and handling.

- Minimal Risk: The geomembrane's construction eliminates the risk associated with micro-probes, ensuring enhanced safety during application.

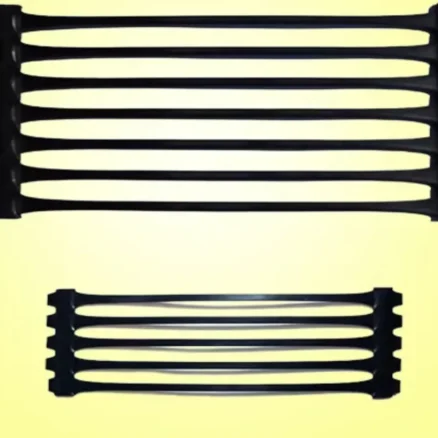

Geonets – Geonet in Road Construction

LS Trading is a famous manufacturer in India and a global exporter of premium quality geonet that is highly durable and perfect for soil drainage and landfill site. We export our products worldwide including the USA, United Kingdom, United Arab Emirates, Australia, and Gulf Countries. Call us or enquire about Geonets Price Now.

It is a planar product and is made up of ribs in two directions. It is made in such a style that it helps to pass on the fluids in both high-load and low-load transmissions, such as landfills for high-load, drainage, and methane gases for low-load transmission. As it is harder compared to geotextile and geogrids because of its stiffness and uniform structure, it can bear high loads at very small deformations and improve the roadbed bearing capacity.

Geonet is also called drainage Geonet, which are being used for any purpose or applications such as water drainage behind retaining walls, soft soil stabilization, landfill leachate collections under building foundations, pavement, and roadway drainage, water leaking from rocky slopes, sea coast slope protection, erosion control, under the sports fields, methane gas collections, dirty water under the motorways, base reinforcement.

In brief basic function of Geo fabric is fluid transmission, protection, erosion control, filtration, reinforcement, and separation.

Our professional highly experienced quality testing team ensures that Geonet Price in India is manufactured keeping in mind strict measures of quality control by following international standards to maintain the highest quality of the Geonet and provide the best service to our customers.

Features:

- Chemical Resistance and Aging Resistance

- Erosion Resistance

- Excellent Flexibility and Durability

- Tensile Strength

- It can be made with all polymeric materials

- It provides shear strength

- Harder than geotextiles and have large voids within the material

- Prevents the surface of the land from the erosion

- Protecting dam and rock surface from chemical erosion and sea water corrode

- Strengthen fill materials in geotechnical applications

- Used as liquid or gas collectors

- Used widely in drainage applications

- Improve the quality of the road

- Road segment restoration

- Stop cracking during road extension

- Cost reduction of road repair

- Increase the lifespan of the road

- UV stabilized

Uniaxial Geogrid

LS Trading is a number one Manufacturer of Uniaxial Geogrid globally, making on a large scale with outstanding quality. Many customers use our products to stabilize soils and improve their moisture and nutrient retention.

Uniaxial Geogrid is a type of soil that has been specifically designed to withstand high winds and heavy loads. It is a good option for sites exposed to high levels of wind or weather conditions, such as wind turbines, construction sites, and agricultural fields. Monoaxial Geogrid can also be used in areas where water runoff is an issue. It contains unique properties that help reduce the intensity and amount of water flowing off the site. LS Trading is one of the best manufacturers of monoaxial Geogrid in the country and provides Geo grid related products worldwide.

High-density polyethylene (HDPE) uniaxial geogrid price is a type of geo grid that has been used in construction since the 1940s. They are designed to be used on both highways and in industrial settings, but they have become more popular with the construction industry in recent years.

HDPE uniaxial geogrid is made from high-density polyethylene (HDPE) plastic. The density of this material makes it strong enough to withstand heavy weight loads without deforming or cracking. It also has good tensile strength, which means it can hold its shape under stress.

In addition to being strong and flexible, HDPE uniaxial geogrid also have good abrasion resistance, so they can withstand rough surfaces without tearing or ripping apart. They're also resistant to chemicals like gasoline or oil, making them safe for use around fuel tanks and other areas where chemicals may be present during installation or use.

Features:

Uniaxial geogrids are a type of soil that has a uniaxial orientation. This means that the grains in the soil are oriented in one direction only. Uniaxial geogrids have many benefits for soil erosion control, including:

- They provide a stable foundation for plant growth and prevent erosion by water and wind

- They resist compaction and improve aeration and drainage

- They reduce the amount of water required to retain moisture in the soil

- They improve the physical and chemical condition of the soil by holding more air, water, and nutrients.

- Good Creep Resistance

- Quick Installation

- High Tensile Strength

Polyester Geogrid

Polyester Geogrid or PET Geogrid is one of the most common options for new construction today, but many people ignore its existence. There are some benefits to investing in Polyester geosynthetic that you should know about.

As the world becomes increasingly environmentally conscious, people are looking for ways to reduce their impact on the environment. One way to do this is by using alternative materials and solutions instead of traditional ones. Poly Geogrid is one such solution, as it has a low environmental impact and can be used in various applications. By understanding how Polyester Geogrid works and what advantages it offers, you can get the most out of this versatile material and positively impact the planet. Singhal Industries Pvt. Ltd. is the main manufacturer Geogrid related products and exporter to USA, United Kingdom, United Arab Emirate Australia and worldwide.

Polyester Geogrid is a manufactured product that consists of a grid of tiny polyethylene beads bonded together in a continuous sheet. The beads are made from recycled plastic and are available in various standard sizes. The Geogrid is typically laid down on top of the ground but can also be laid into trenches or existing structures such as retaining walls. PET Geogrid isn't an earth-moving product; it will work best when combined with other erosion control elements, including proper landscaping practices, erosion control fabric, and other erosion control methods like mulch and rock. According to the manufacturer's specifications, operators are typically issued Geogrids by the ton, including the grid size to be used.

Features:

Polyester Geogrid has many features that make it an ideal material for many applications. Some of the features that make polyester Geogrid a perfect material for many applications are its low cost, durability, and resistance to weathering.

One feature that makes polyester Geogrid an ideal material for many applications is its low cost. Polyester Geogrid is a relatively inexpensive material and can be purchased in bulk. This makes it a perfect solution for applications where cost is a concern, such as fencing and landscaping.

Polyester Geogrid is also durable. Unlike other materials, such as wood and metal, polyester will not decay over time. This makes it an ideal material for applications where durability is essential, such as fencing and landscaping.

Finally, polyester Geogrid is resistant to weathering. Weathering is the gradual deterioration of a material caused by exposure to elements such as sunlight, rain, and wind. Polyester Geogrid resists these elements better than most other materials, making it an ideal material for applications where durability is essential, such as landscaping and fencing. For the reasons listed above, polyester Geogrid is a durable and cost-effective material that works well in applications where strength and durability are critical.

Advantages:

Polyester Geogrid has many advantages over traditional materials, including:

- It is resistant to moisture and fungus

- It is lightweight and easy to transport

- It can be easily dyed or printed to match your needs.

- It is fire-proof, making it an excellent choice for outdoor use.

Warning Tape Tile

LS Trading stands at the forefront of delivering superior quality Underground Cable Protection Covers that offer exceptional visibility, easy installation, and unmatched durability. These covers are designed to safeguard underground utility cables, particularly high-voltage ones, from potential damage.

The key highlight of these cable protection covers is their exceptional durability and resistance to impacts. Despite this ruggedness, they remain lightweight and incredibly user-friendly, making them a breeze to install. These covers are intelligently designed with seamless joints, overlapping edges, and secure fastening using plastic pegs, ensuring a consistent level of safety.

The Cable Protection Tile is specifically designed using heavy-duty plastic material known as Polyethylene. This robust material provides a strong defense against the threats posed by construction equipment and machinery. These tiles serve a dual purpose: not only do they act as markers, but they also offer substantial impact resistance to the cables they shield.

The top surface of the Cable Protection Tile is laminated with a colored Warning Tape, which serves as a visual indicator. This tape bears a printed warning message, effectively communicating the presence of buried cables and the potential hazards they pose. This serves as a proactive alert to anyone who might be involved in digging or construction activities in the vicinity.

The Warning Tape Tile is thoughtfully engineered to remain in optimal condition even when buried underground for extended periods. It retains its integrity and clarity, ensuring that the warning message remains visible over time. Furthermore, these tiles are suitable for protecting both high-voltage and low-voltage cable utilities, making them versatile solutions for various cable types.

At LS Trading, we offer the capability to print warning or alert messages in any language or text using non-detectable ink. Our product lineup encompasses warning tape tiles of diverse sizes, colors, and materials. We also accommodate customization requests, including the addition of company logos and phone numbers, tailoring the tiles to our customers' specific needs.

The production of our underground cable protection tiles is overseen by a team of experienced professionals who uphold rigorous quality control standards. This commitment to quality aligns with international benchmarks, ensuring that the manufactured tiles consistently meet high standards. Our objective is to deliver top-tier products and services to our valued customers, maintaining the utmost level of quality throughout the process.

Features:

Following are the Features of Polymeric Cable Cover

- Manufactured from HDPE, LDPE, LLDPE

- Complies with international standard like AS4702-2000 and ENA-TS 12-23

- Used to manufacture high quality resin

- High Impact Resistance

- Non-deletable and scratch proof

- Low Installation cost

- High Impact Strength

- Connected to each other for longer distance through pegs or cable tie

Following are the advantages of Polymeric Cable Cover

- Very simple and easy to install. Only unroll on-site and it’s done

- Higher level of protection for buried cables

- Low Transportation cost due to heavyweight

- Cost effective

- Highly visible warnings due to bright colour

- Provides high level of durability

- Rot and termite resistant

- No risk of personal injury due to highly visible warnings